SHOT COUNT MONITOR

Resistance weld Weld Points monitoring system

S C M - 0 4 4 A

SCM-044A is a dedicated machine that easily prevents the outflow of defective products that have been forgotten to weld at spot welding sites. By sensing the welding current of processing, the welding point is counted up, and the operator is notified of completion with an alarm and LED flashing at the set number of welding points. By monitoring the number of weld points for all products at the welding site, the outflow of defective products is suppressed.

Benefits

-

In order to be able to handle the various types of spot welding machines you have, it has an original sensor and detects and counts the welding current. (No signal wiring with the welder is required)

- The unit is equipped with a magnetic foot and is easy to place.

-

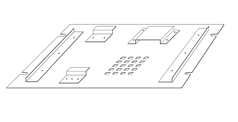

Even when welding multiple parts with different numbers of points to one product, it is possible to monitor each number of points with up to four parts.

-

You can set the number of welding points (SHOT) in the product and the count of the finished product quantity (LOT) respectively.

-

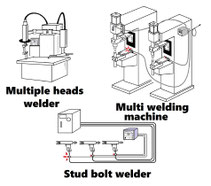

Up to 4 can be handled for work using multiple processing heads. (Effective when working with multiple welding machines, stud welding, etc.)

- SCM-044A supports up to 4 ports (for 4 heads) The SCM-024A supports up to 2 ports (for 2 heads).

It is easy to manage small production volumes.

For managing multiple machining heads

It has 4 sensor input ports up to a-d, and the number of welding points can be set for each port.With this function, it is possible to handle production control of two-head welding machines, operations in which two welders are placed side by side to process under different welding conditions, and work in which stat bolts with different thread diameters are welded in products.

Can be reset at work

Management of the number of weld points produced

You can easily manage the points of your welders, so you don't have to install expensive automated production machines or buy new, expensive welder.

the best spot welding shortage

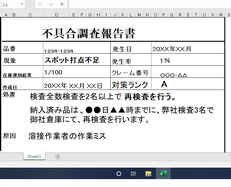

Are you worried about unnecessary man-hours by intensifying inspections by leaking products that do not have enough points to customers?

Welding point shortages occur at welding sites. The best way to deal with it is to monitor it at the work site.

Careless mistakes for simple work are troubles that can occur even for excellent workers.

You can quickly monitor to your welding machine

The original sensor can sense welding anywhere in the welding current flow conductor.

There is no need for difficult signal wiring with the welder.

If it does not interfere with the welding work, the installation of the sensor is completed simply by fixing the sensor to the conductor through which the welding current flows.You can check the sensor being monitored by the LED at the tip of the sensor. Even when working with multiple machining heads, it is possible to prevent machining head mixup.